"The first 3D printing intelligent casting project in Gansu", "the most advanced 3D sand mold printing equipment in China" and "the process technology is in the leading position in China"... Recently, the first 3D printing green intelligent casting project in Gansu Province was implemented in the Western Heavy Industry Company of Jiuquan Iron and steel group. The project broke the stereotype of "stupid, big, black and rough" in the foundry industry and successfully realized the transformation and development to "green intelligence".

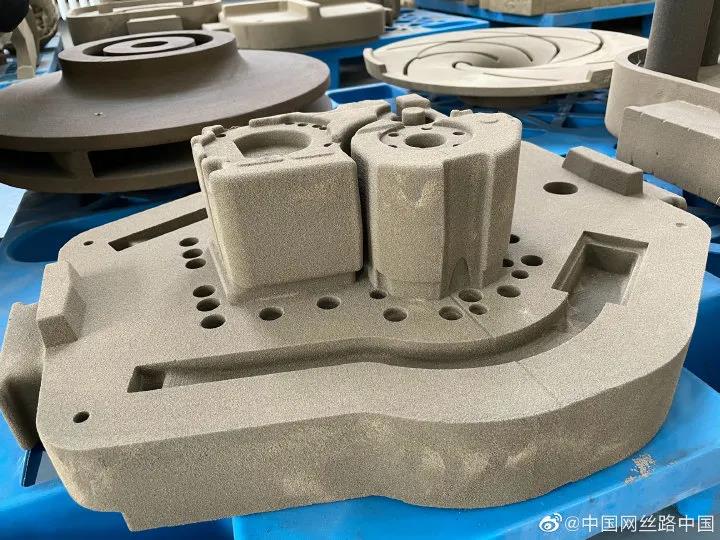

Zhang Yuxiang, director of the Organization Department of the Party committee of Gansu Jiuquan Iron and Steel Group West Heavy Industry Co., Ltd., said that compared with the traditional casting process, the 3D printing green intelligent casting equipment printing technology does not need any special auxiliary tools and is not limited by the batch size. Only one programmer inputs the parameters into the computer, and the sander will start to operate under the instruction. After 2000-2500 layers of stacking, a 1m high product can be printed in 13-15 hours.

The printed product has high dimensional accuracy, short casting cycle and high integration, and the added value of the product is increased by more than 50%. The thermal recycling sand treatment process can also realize zero discharge of solid waste of casting sand.

"3D printing is not only efficient, but also widely used." it is reported that 3D printing is actually a production method of rapidly generating products by using additive manufacturing technology and taking digital drive as the core.

At present, Jiuquan Iron and Steel's 3D printing facility can realize the industrial mass production of high-end castings. The products can be used in hydropower, nuclear power, special vehicles, aviation, military industry and other fields, and the application prospect is very broad.